Services

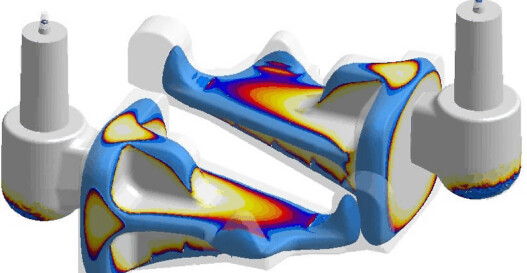

Castings aren’t something you can just buy “off the shelf” – each one represents an individual solution to a technical puzzle, based on the requirements of the customer and the specific application.

HERE AT BRECHMANN-GUSS

we are casters who prize communication, cooperation, and being able to see eye-to-eye with our customers – you –, in order to succeed in finding the best possible solution for your needs. Our success is linked to yours – we can only survive as a company supplying parts for you if your products are successful with your customers in turn.

There is more to these terms than seen at a glance…or did you know that, for example, modern high-temperature insulation materials can sink the outer temperature of a turbocharger from 600° to 200° C (1110° – 390° F) – and that this drop in temperature plays a significant role in improving emissions? Or that rolled ADI parts survive mechanical loading that guarantees that comparable steel components will fail? Or…well, look around and see for yourself!